KGHM ZANAM S.A. — a history of generations of people and machines

History of production at KGHM ZANAM S.A.

The history of KGHM ZANAM S.A. dates back to the beginnings of copper ore mining in the Polish Copper Belt when work began on the establishment of a national production base for mining in the 1960s. From the earliest days, the Company has aimed to provide reliable, efficient and innovative solutions to support mining processes at Poland’s largest mines. Therefore, as one of the key entities of the KGHM Polska Miedź S.A. Group, it has played a fundamental role in the mechanisation of copper ore mining in the country over the past decades.

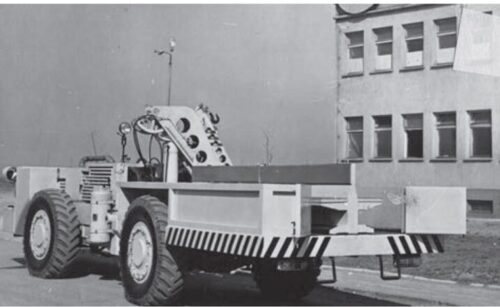

The first steps towards the independent production of mining machines and equipment were taken in the 1970s when plants were established to design and manufacture equipment dedicated to the specifics of copper ore mining in Poland. In 1971, Legmet`s specialists developed a design for a mine truck with a reinforced chassis and an 8-tonne loading capacity. Subsequent decades brought systematic development of the technological base and machinery, allowing KGHM ZANAM S.A. to become not only a supplier of machines to the plants of its mother company KGHM Polska Miedź S.A. but also a partner for many mining companies on international markets.

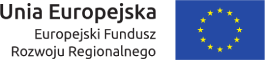

The current operation of KGHM ZANAM S.A. machines within KGHM Polska Miedź S.A.

Over the years, the number of KGHM ZANAM S.A. machines operated in the mines of KGHM Polska Miedź S.A. has increased significantly. Thanks to their reliability and high quality, these machines now form the backbone of the fleet at the Lubin, Rudna and Polkowice-Sieroszowice mines, as well as at Przedsiębiorstwo Budowy Kopalń “PeBeKa”, a mine construction company.

Today, an impressive number of KGHM ZANAM S.A. machines are in use across the mines and mining operations of KGHM Polska Miedź S.A., totalling to about 556 pieces. On the other hand, Przedsiębiorstwo Budowy Kopalń PeBeKa S.A. uses additional 190 machines. A detailed analysis shows that our machines are an indispensable support for the mining processes at each mine. This proves that domestic engineering and local production facilities can compete well with international giants and that our machines are firmly embedded in the landscape of copper ore mining in Poland.

Striving for decarbonisation and innovation

KGHM ZANAM S.A. is continuously developing technologies related to the electrification of mining machines, introducing low- and zero-emission drives. In this way, the company not only supports the decarbonisation of the mining industry but also meets the highest environmental and performance standards. Developing modern electric drives and minimising environmental impact is one of the company’s priorities for the future of the mining industry.

ZANPER at the 33rd Economic Forum in Karpacz

Innovation and local patriotism

KGHM ZANAM S.A. has always emphasised close cooperation in the local market and the adaptation of its machines to the specific operating conditions found in the Polish Copper Belt. It is worth noting that the employment structure of KGHM ZANAM S.A. is closely linked to the communities in which the mining plants of KGHM Polska Miedź S.A. operate. The proximity of the mines and the working environment makes the company’s employees particularly motivated to provide reliable and safe technological solutions. This ensures that our products not only meet the highest quality standards but also effectively support mining processes, contributing to increased efficiency and safety in underground operations.

In 2026, KGHM ZANAM S.A. will be celebrating its 60th anniversary. The six decades of operations are a history of continuous development, innovation and the commitment of thousands of employees who have shaped Poland’s copper ore mining industry with their knowledge and expertise. This anniversary will serve as an opportunity to take stock of achievements but also as a moment to look to the future, focusing on further expansion, reinforcing our position as an industry leader and implementing cutting-edge technology and eco-friendly solutions.