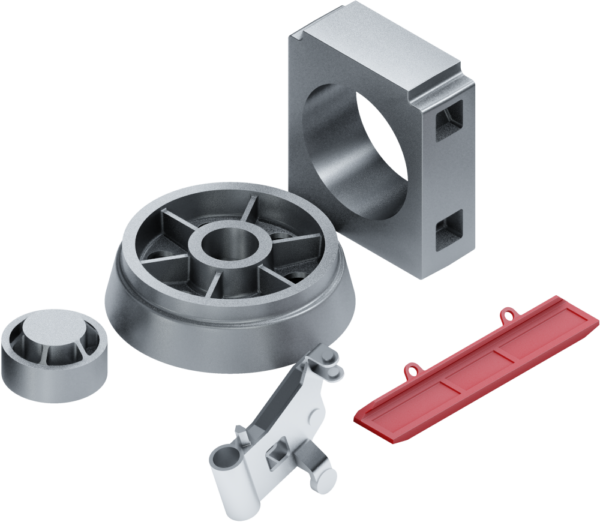

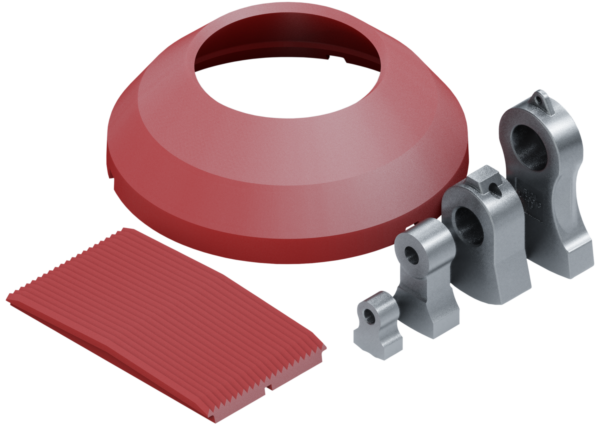

Castings

KGHM ZANAM manufactures cast steel and cast iron castings in a wide range of weight options, offering low-and medium-volume production as well as one-off production. Heat treatment of castings is carried out in modern and fully automated annealing furnaces. The products manufactured are characterised by durability and high quality. Castings are made using self-hardening mass technology – FLOSTER. By using electric arc furnaces, we obtain liquid metal of high quality, with the right chemical structure and special properties.

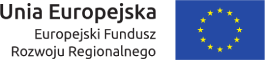

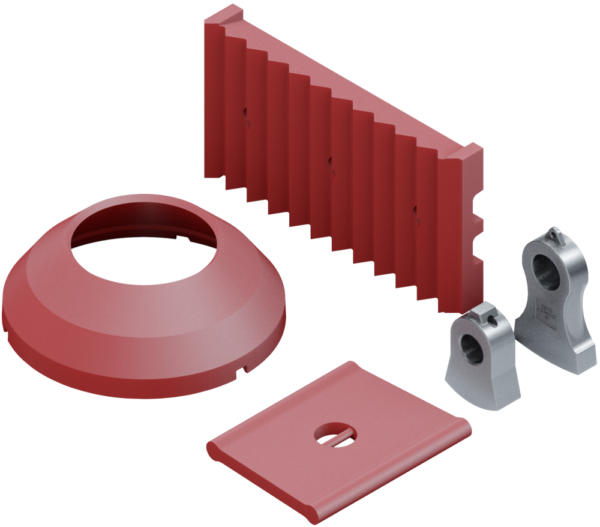

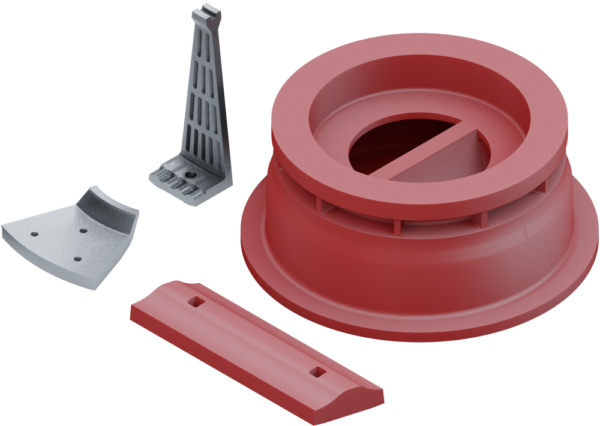

We offer our customers cast steel and cast iron castings, produced in various grades depending on the application. These include castings for jaw, impact, hammer or cone crushers, as well as elements of mills for processing metal ores and other raw materials. At KGHM ZANAM, we also manufacture castings of track chain links, customised for excavators, and floor accessories used in underground mining. Our foundry casts parts for haul trucks, conveyors and other equipment used in mines.

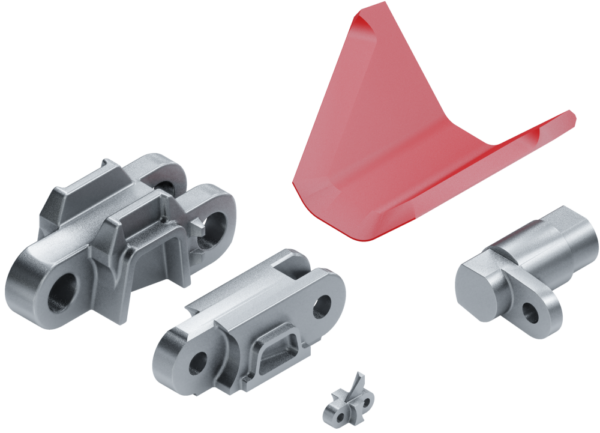

At KGHM ZANAM we prepare castings using cast steel made in accordance with national and European standards. Structural components can be made from different grades of structural carbon cast steel, structural alloy cast steel, as well as alloys for thermal upgrading and quenching, characterised by increased strength and wear resistance. The use of high-quality alloys guarantees a long service life for individual machine components. Depending on the type of components and the strength parameters of the manufactured segment, we select the appropriate type of cast steel and cast iron from a wide range of metal alloy grades. Orders for castings are carried out using modern production facilities.

We use Magma Soft software, which allows us to optimise the casting process and shorten the order completion time right from the design stage.

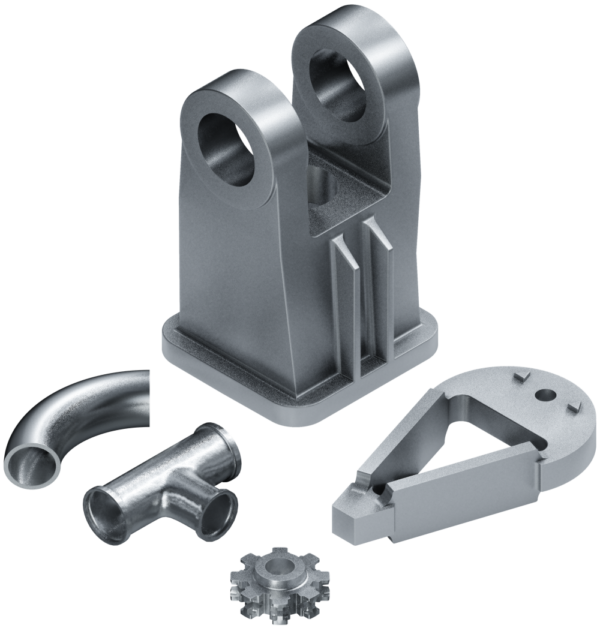

In the KGHM ZANAM foundry, we also carry out heat treatment processes on castings using modern automatic furnaces, such as:

-

normalising annealing,

-

quenching,

-

thermal upgrading,

-

hardening,

-

tempering,

-

softening annealing,

-

stress relief annealing.

Showing all 7 results