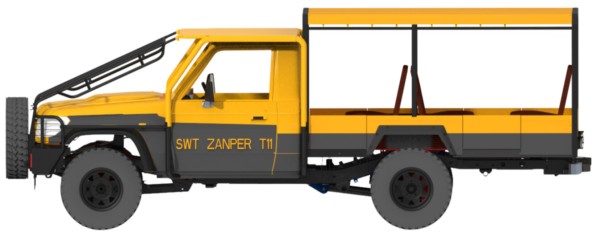

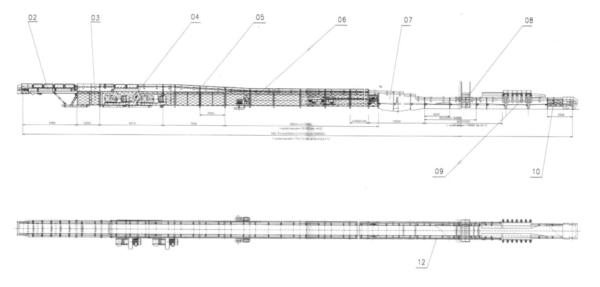

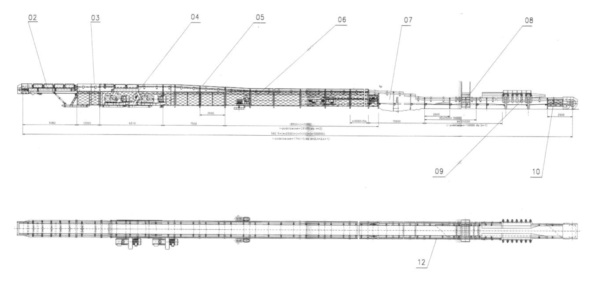

Mining

machinery and equipment

We manufacture mining machinery that are responsible for the preparation and performance of the manufacturing process related to the extraction and haulage of excavated material in non-methane, underground non-ferrous metal ore mines and mines that extract minerals other than hard coal.

Technical

services

We provide EPC services for investments, maintenance and overhaul services, transport and forwarding services as well as specialist services on the premises of underground mines (services associated with mining, machine servicing, and underground transport).

Castings

We manufacture castings in a wide range of weight options, offering low- and medium-volume production as well as one-off production. Heat treatment of castings is carried out in modern and fully automated furnaces. The products are characterised by durability and resistance to abrasion.

Steel structures

We are a recognised manufacturer of large-size welded steel structures. The products that we manufacture include, among other things, hoisting equipment (skips), cages, and shaft hangers. We are able to manufacture any steel structures based on technical documentation.

Higher

safety

standard

Products

We are one of Poland’s largest manufacturers of mining machinery and equipment. We also manufacture equipment used in handling systems, transport units, quarrying, and open-pit mines. In addition, we are a major player in cast steel and cast iron castings.

Showing 13–24 of 60 results

Technical

services

We provide EPC services for investments, maintenance and overhaul services, transport and forwarding services as well as specialist services on the premises of underground mines (services associated with mining, machine servicing, and underground transport).

IMPLEMENTATION

OF INVESTMENTS

Comprehensive implementation of investment projects, provision of modernisation and maintenance services at industrial facilities.

SERVICING

OF SPMM

Warranty and post-warranty technical servicing of self-propelled mining machinery.

MINING

WORKS

Comprehensive provision of services related to preparatory works, underground construction, belt conveyor transport, and blasting works.

TRANSPORT

AND FREIGHT FORWARDING SERVICES

Transport and freight forwarding services as well as full logistic support for domestic and foreign entities.

About us

KGHM ZANAM S.A. is one of Poland’s largest manufacturers of machines and equipment for the mining sector and part of the KGHM Polska Miedź S.A. Group of Companies, supporting its core process line. We are the main supplier for this strategic state-owned company, which is the world’s leading manufacturer of copper and silver.

1

We are characterised by versality and run both manufacturing and service operations.

2

We rely on innovations and knowledge-based development

3

We cooperate with leading manufacturers and suppliers

News

Stay up-to-date with us. Below you will find news and messages associated with the life of the Company.

KGHM ZANAM S.A. in figures

Over 50 years of activity allow us to share many interesting facts with you.

6525 m3

the volume of the concrete used to build a flash furnace and an electric furnace

4

the number of continents on which we have presented our offer during trade fairs

2300

this is the number of employees

5000 kg

the maximum weight of the heaviest casting produced by

KGHM ZANAM

48600 kg

the weight of the heaviest machine that we have manufactured – LKP-1701 loader

1895

the number of self-propelled mining machinery supplied to KGHM Polska Miedź S.A. mines over the last twenty years

170 km

the length of conveyor routes built by us in

KGHM Polska Miedź S.A. mines

354 t

the volume of reinforcing steel used to build a flash furnace and an electric furnace

History

The history of KGHM ZANAM dates back to the 1960s and is associated with the parallel development followed by a merger of two entities established in copper mining plants – Legmet from Legnica and Zanam from Polkowice.

1966

Establishment of Legmet

on 1 October 1966, the Minister of Heavy Industry signed a decision to establish the Legnica Mechanical Plant for Non-Ferrous Metals (Legnickie Zakłady Mechaniczne Metali Nieżelaznych)

1976

Establishment of Zanam

on 1 January 1976, the Central Repair Workshop (Centralne Warsztaty Remontowe) was renamed the Machinery Repair Plant (Zakłady Naprawcze Maszyn – Zanam)

2003

Merger of DFM Zanam

and ZM Legmet

on 28 April 2003, the extraordinary shareholders’ meeting decided to merge DFM Zanam and ZM Legmet

2013

Establishment of

KGHM ZANAM

In March 2013,

DFM ZANAM-LEGMET was renamed

KGHM ZANAM in order to emphasise its relationship with the copper tycoon

Management

Board

The Management Board of KGHM ZANAM consists of qualified and experienced managers. Members of the KGHM ZANAM Management Board have broad knowledge of and long practical experience in holding important functions in entities from the heavy industry sector (fuel and energy, chemical, electrical equipment, and defence industries)

|

|

|

|

|

|

Wojciech Boczar Chairman of the Supervisory Board |

Paweł Potęga Deputy Chairman of the Supervisory Board |

Ireneusz Oszczęda Secretary of the Supervisory Board |

Małgorzata Bogdanowicz Member of the Supervisory Board |

Leszek Ziętkowski Member of the Supervisory Board |

Contact

We advise you to contact a given person responsible for a given area directly or to use the application form. We will make every effort to reply to your inquiry as soon as possible.

- BUSINESS CONTACTS

- ADMINISTRATIVE OFFICE

- MEDIA AND PR / COMMUNICATIONS

- DATA PROTECTION SUPERVISOR

- SALES REPRESENTATIVES

- RECRUITMENT AND TRAINING

Director of the Sales, Marketing and PR DepartmentWojciech Keep |

Director for Investment ProjectsMarcin Kowalczyk |

Sales Team Manager for Castings and StructuresRyszard Krasowski |

SMG Production DirectorEdward Paszko |

|

tel. +48 76 847 09 05 sekretariat@kghmzanam.com |

|

tel. +48 76 / 847 09 38 tel. +48 76 / 746 97 60 |

|

Wioletta Cyganowska |

Estonia EVAS B&P ASPõllu 6, |

|

tel. +48 / 76 74 69 726

|